Shijiazhuang Yanhui Dye Co.,Ltd is revolutionizing the denim industry with their innovative Liquid Indigo Blue dyeing process. We has recently introduced a new environmentally friendly Liquid Indigo Blue,a vat Indigo Blue liquid form,which is more beneficial to denim dyeing compared to traditional dyeing methods.

In addition, the Liquid Indigo Blue dye is more cost-effective and requires less time for the dyeing process, making Liquid indigo an ideal choice for denim manufacturers looking to improve their production efficiency.The Liquid Indigo Blue dyeing process is a game-changer for the denim industry, offering a more sustainable and efficient way to color denim fabrics.

The relevant dyeing processes for Liquid Indigo Blue are as follows:

1.Yarn pretreatment

Textile printing and dyeing table

pad dyeing machine

Before dyeing, soak the white yarn in penetrant for a few minutes to make the yarn soft, then rinse it with clear water, and then roll and dry it with the pad machine.

The water can be squeezed out through rollers in the production line or through a small rolling mill as shown in the photo to the right.

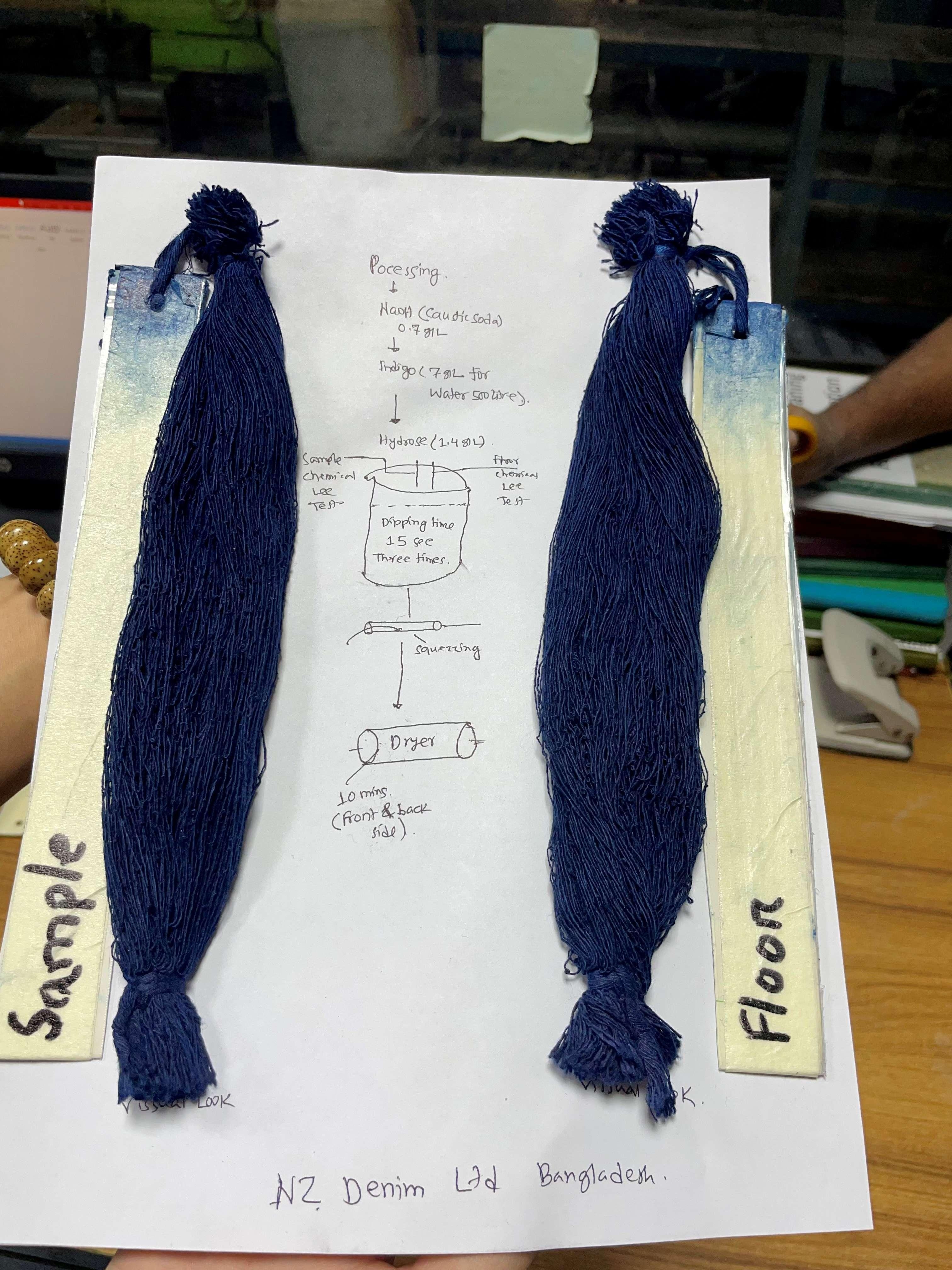

2.Preparation Of Dye Solution

First, weigh 7g of reducing Liquid Indigo Blue sample sample into 500g of water.

Secondly, add 0.7g of caustic soda.

Then, add 1.4g of Sodium Hydrosulfite.

Finally, Stir evenly, fully dissolve, and start dyeing after 5-10 minutes.

This is the dye solution for our Chinese and another company's liquid indigo, both 30% content and same ratio. If liquid indigo is 40% content, then the amount of liquid indigo taken is 5.185 grams, and the rest remains same.

Pay attention to : The ratio of pushing powder is 1: 0.1: 0.2

3.Yarn Dyeing (three dips and three pads)

The first step :Take out the water-soaked yarn, wash it with clean water, roll it dry, smooth it, then start dyeing it, soak it in the dye solution for 15 seconds, then oxidized for 15 seconds and then roll and dry it with the pad machine.

The second step:Smooth the dried yarn, then soak it in the dye solution for 15 seconds, then oxidize it for 15 seconds, and then roll and dry it with the pad machine.

The third step:Smooth the yarn that has been padded to remove moisture, then immerse it in the dyeing solution for 15 seconds, and then oxidize it for 15 seconds before roll and dry it with the pad machine.This completes the dyeing of three dips and three pads.

Finally, making the sample board by drying and binding .

Our liquid indigo compared with BC yarn sample.

This is the comparison result of our on-site sampling at a denim factory in Bangladesh, and our dyeing process is attached.

4.Rinse Dyed Yarn

After dyeing, take a small amount of dyed yarn samples and bleach wash them to see the color depth after rinsing.

Overall, the introduction of the Liquid Indigo Blue dyeing process by Shijiazhuang Yanhui Dye Co., Ltd. is a significant step forward for the denim industry. By offering a more sustainable and efficient way to color denim fabrics, “YANHUI DYE” is playing a key role in driving positive change within the industry. With our environmentally friendly features and superior dyeing performance, the Liquid Indigo Blue is set to revolutionize the way denim is dyed, setting a new standard for sustainable and efficient denim production.

Post time: Dec-27-2023