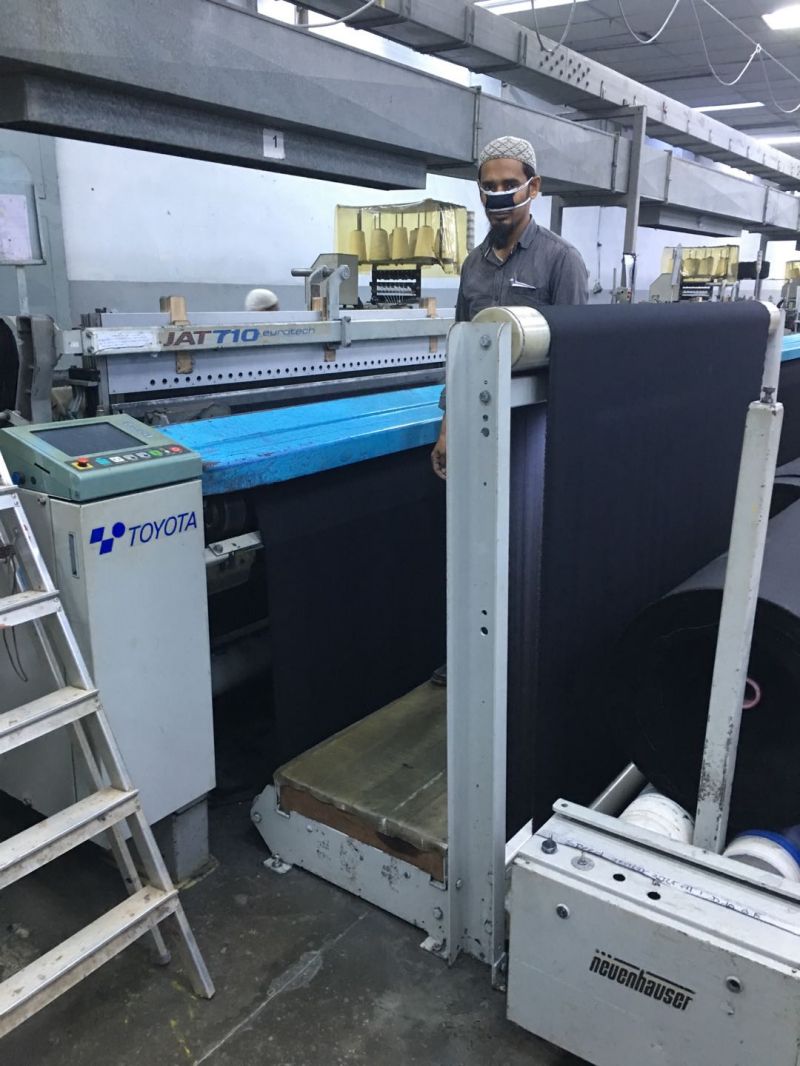

Denim clothes dyed with Sulphur Black BR are very popular. The dyeing equipment we use adopts the method of continuous printing and dyeing of warp shaft, and the production process is relatively mature. Sulphur Black BR is insoluble in water, but, it can be dissolved in sodium sulfide solution by revert to hidden color. This hidden color body can be dyed on cellulose fibers to complete the dyeing process. The properties of sulphur dyes are similar to those of direct dyes and vat dyes. The reductant of Sulphur Black BR, sodium sulfide, has a weak reducibility, so it is not easy for sulphur black to be reduced. At the same time, the Sulphur Black BR is relatively stable at high temperatures. When the Sulphur Black BR dye is reduced and dissolved with sodium sulfide, it generates thiophenol, which is converted into sodium sulfide and dissolved.

The dye solution composed of sulphur dyes reduced by sodium sulfide is not stable enough. The Sulphur Black BR dye only needs to be fully washed to remove the residual sodium sulfide on the fabric and can be fully oxidized by air. The amount of sodium sulfide used to restore and dissolve Sulphur Black BR cannot be accurately calculated.

After dyeing the fiber with Sulphur Black BR dye, it must be oxidized to make it become insoluble dye and fixed on the fiber. sulphur black can be oxidized as long as it is washed and ventilated. When dyeing with dyes with fast oxidation rate of leuco compound, if the dye is exposed to air or sodium sulfide is insufficient, it will be oxidized prematurely to produce stain. Dyes other than sulphur black can be treated with fixing agent to improve the color fastness. Copper sulfate can catalyze the brittle fiber of Sulphur Black BR, so copper sulfate cannot be used for fixation.

Post time: Oct-28-2022